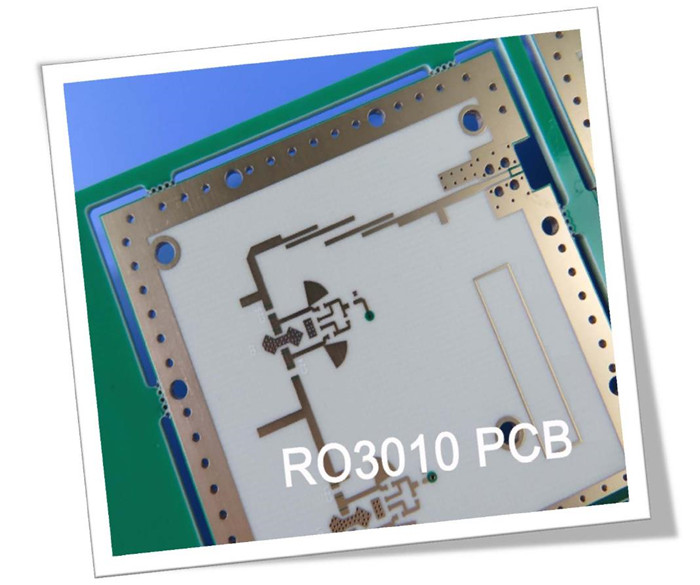

Rogers 3010 PCB RO3010 High Frequency PCB With 5mil, 10mil, 25mil and 50mil Coating Immersion Silver, Gold, Tin and HASL

(Printed Circuit Boards are custom-made products; the images and parameters shown are for reference only)

Introduction

Hello Everyone,

Today, we are discussing RO3010 high-frequency PCBs.

Rogers RO3010 high-frequency circuit laminates are ceramic-filled PTFE composites designed for commercial microwave and RF applications. This material is characterized by exceptional electrical performance and stable mechanical properties, enabling designers to create multi-layer boards without encountering warpage or reliability issues.

Key Features and Applications

1.Superior Mechanical Properties: RO3010 demonstrates excellent reliability in stripline and multi-layer board constructions, particularly under varying temperatures.

2.Uniform Mechanical Stability: This material is compatible with epoxy glass multi-layer hybrid designs, ensuring consistent performance.

3.Low In-Plane Expansion Coefficient: The material's expansion coefficient matches that of copper, enhancing the reliability of surface-mounted assemblies. It is ideal for applications sensitive to temperature fluctuations and offers outstanding dimensional stability.

PCB Material: |

Ceramic-filled PTFE composite |

Designation: |

RO3010 |

Dielectric constant: |

10. 2 ±0.3 (process) |

11.2 (design) |

|

Layer count: |

2 Layer, Multilayer, Hybrid PCB |

Copper weight: |

0.5oz (17 µm), 1oz (35µm), 2oz (70µm) |

Laminate thickness: |

5mil (0.127mm), 10mil (0.254mm), |

25mil (0.635mm), 50mil (1.27mm) |

|

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, Immersion Silver, Immersion tin, OSP etc.. |

|

|

RO3010 high-frequency PCBs are offered in double-sided, multi-layer, and hybrid constructions, with finished copper weights ranging from 0.5oz to 2oz and thicknesses from 0.13mm to 1.3mm. The maximum size is 400mm by 500mm, with various surface finishes available, including bare copper,hot air leveling,immersion etc.

Typical Applications

Automotive radar applications

GPS antennas

Power amplifiers and antennas

Patch antennas for wireless communications

Direct broadcast satellites

The standard color for RO3010 PCBs is white.

The manufacturing process for RO3010 high-frequency PCBs closely resembles that of standard PTFE PCBs, making it suitable for high-volume production and providing a competitive advantage in the market.

We offer a diverse selection of high frequency materials, including Rogers 4000 series, 3000 series, 5000 series, and 6000 series, as well as Taconic TLX and TLY series, and the Chinese F4B series.

If you are interested in our products, please feel free to reach out.

Thank you for reading!

Appendix: Data Sheet of RO3010

RO3010 Typical Value |

|||||

Property |

RO3010 |

Direction |

Units |

Condition |

Test Method |

Dielectric Constant,εProcess |

10.2±0.05 |

Z |

|

10 GHz/23℃ |

IPC-TM-650 2.5.5.5 Clamped Stripline |

Dielectric Constant,εDesign |

11.2 |

Z |

|

8GHz to 40 GHz |

Differential Phase Length Method |

Dissipation Factor,tanδ |

0.0022 |

Z |

|

10 GHz/23℃ |

IPC-TM-650 2.5.5.5 |

Thermal Coefficient of ε |

-395 |

Z |

ppm/℃ |

10 GHz -50℃to 150℃ |

IPC-TM-650 2.5.5.5 |

Dimensional Stability |

0.35 |

X |

mm/m |

COND A |

IPC-TM-650 2.2.4 |

Volume Resistivity |

105 |

|

MΩ.cm |

COND A |

IPC 2.5.17.1 |

Surface Resistivity |

105 |

|

MΩ |

COND A |

IPC 2.5.17.1 |

Tensile Modulus |

1902 |

X |

MPa |

23℃ |

ASTM D 638 |

Moisture Absorption |

0.05 |

|

% |

D48/50 |

IPC-TM-650 2.6.2.1 |

Specific Heat |

0.8 |

|

j/g/k |

|

Calculated |

Thermal Conductivity |

0.95 |

|

W/M/K |

50℃ |

ASTM D 5470 |

Coefficient of Thermal Expansion |

13 |

X |

ppm/℃ |

23℃/50% RH |

IPC-TM-650 2.4.4.1 |

Td |

500 |

|

℃ TGA |

|

ASTM D 3850 |

Density |

2.8 |

|

gm/cm3 |

23℃ |

ASTM D 792 |

Copper Peel Stength |

9.4 |

|

Ib/in. |

1oz,EDC After Solder Float |

IPC-TM 2.4.8 |

Flammability |

V-0 |

|

|

|

UL 94 |

Lead-free Process Compatible |

Yes |

|

|

|

|